Sawdust

Recycled Wood Composite: R&D with Plykea

This research and development project explored how to transform sawdust and plywood offcuts into a new kind of material: a recycled wood composite that behaves like wood, but isn’t bound by its traditional limits.

We partnered with Plykea—a company known for creating high-quality, design-led kitchen fronts made to fit IKEA cabinets. Their focus on sustainability and honest materials made them a natural collaborator. They sent us a generous supply of their wood waste: a mix of fine sawdust and larger plywood offcuts, typically discarded.

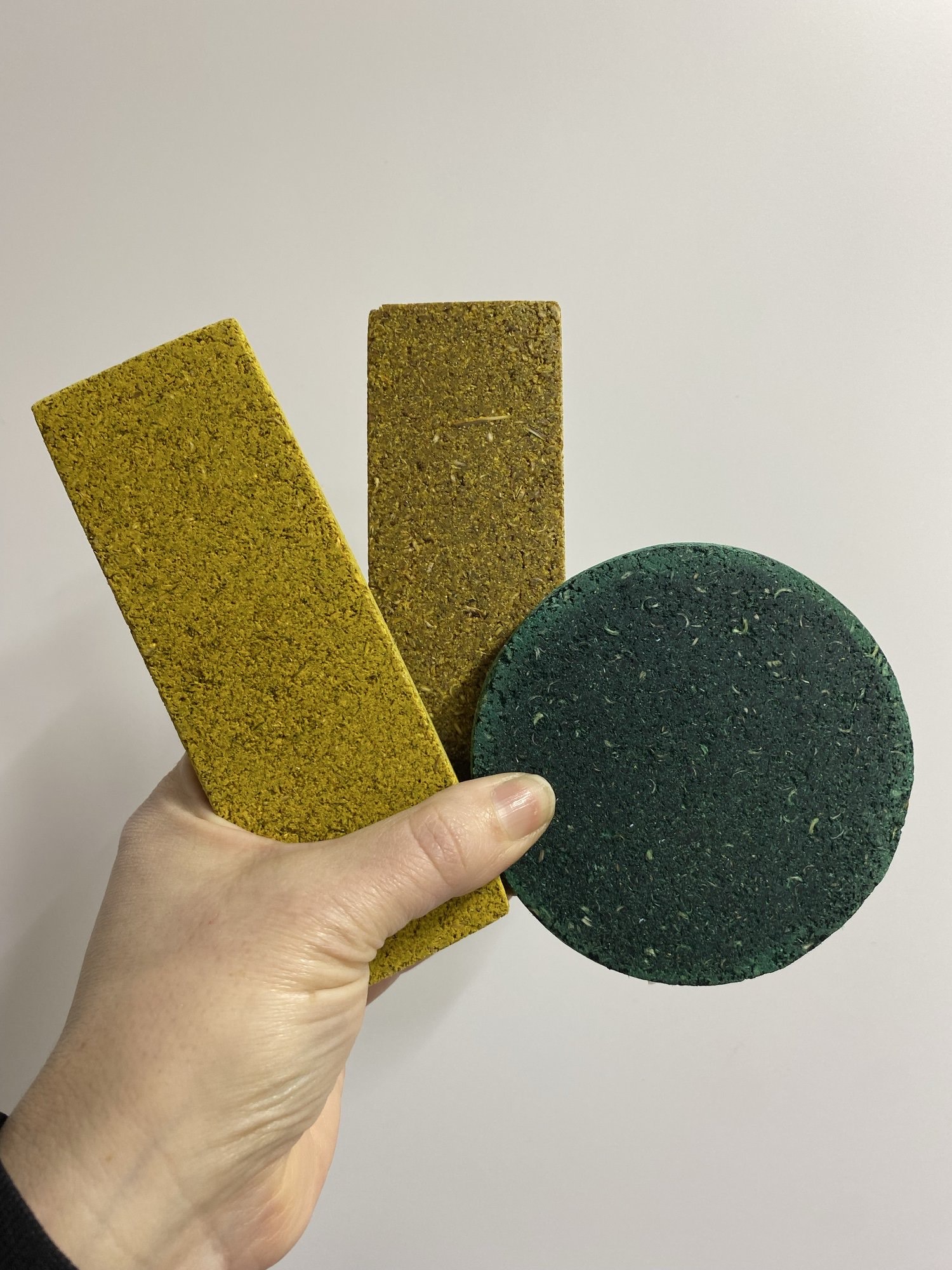

Our aim was to reimagine this material from the ground up. Rather than pressing it back into boards, we experimented with turning it into a castable, sculptural material. We trialled a range of binders, eventually landing on a bio-based epoxy resin known for its low VOCs and sustainable credentials. It allowed us to suspend a remarkably high proportion of waste—up to 90%—within the binder, producing a dense, workable form that remained lightweight.

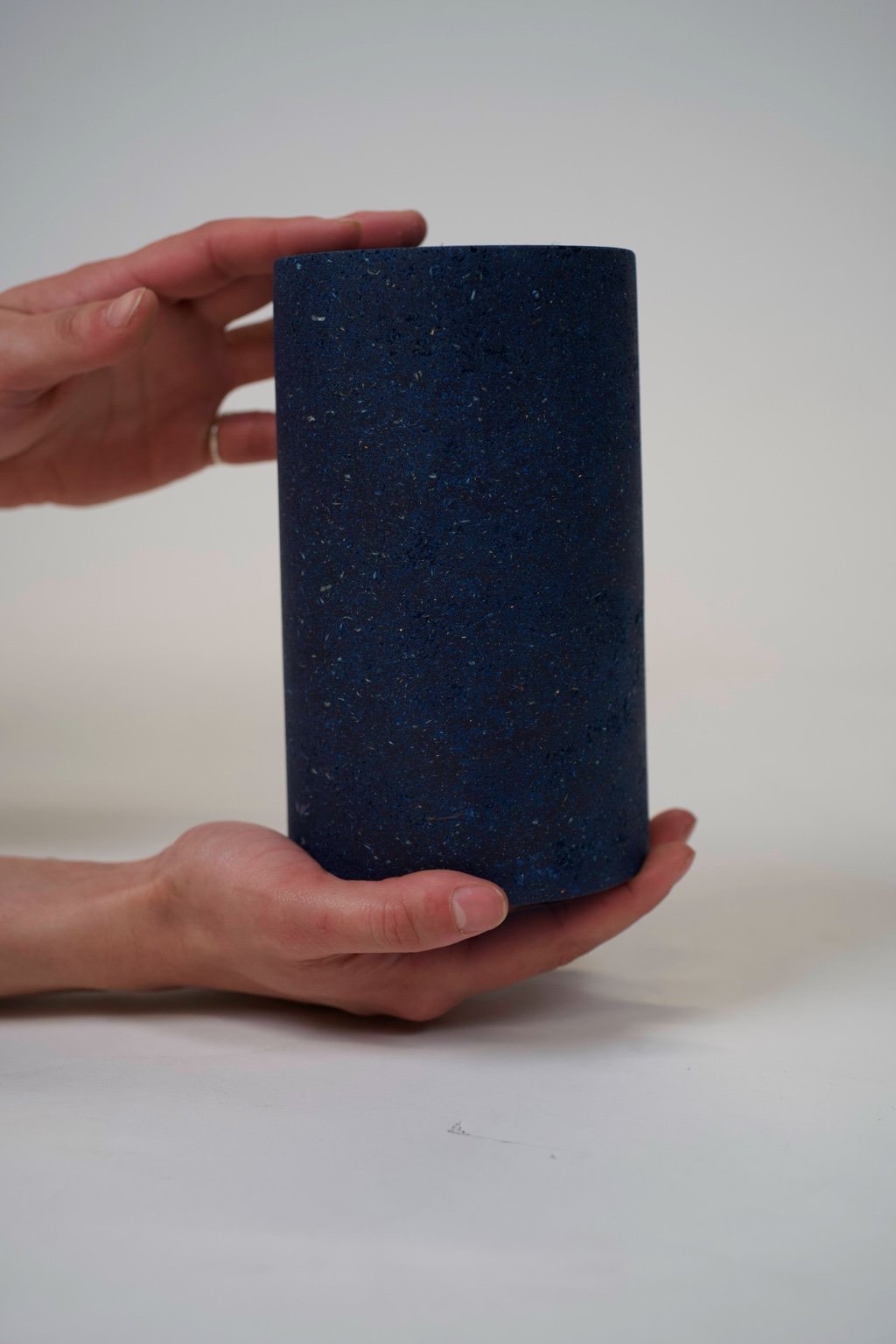

By casting hollow cylindrical moulds just 10mm thick, we could create robust yet featherlight objects. These were then lathe-turned using traditional woodworking techniques, allowing us to sculpt forms as if they were made from solid wood. In reality, each piece was formed from sawdust composite—essentially wood, reimagined.

Throughout the project we also explored colour, incorporating rich greens and deep oceanic blues to highlight the surface texture and suggest a new kind of material beauty.

The result? A lightweight, lathe-turnable, recycled wood composite made from plywood waste—offering a new route for material reuse in design and sculpture. This project is part of our ongoing work to unlock circular potential in overlooked waste streams, and to expand the aesthetic and structural possibilities of waste-based materials.

This project remains ongoing, but it marks an exciting step forward in our material language.

Want to kick off an R&D project? Get in touch here.